Installing a Generator Compartment on the Rear of a Trailer

The rear view of the Arctic Fox 24-5N in stock form. Note how the spare tire is mounted on the center of the bumper making access to the OEM shore shore power cord difficult. We resolved that issue by relocating the shore power cord. That's written up in a different thread here.

The easiest way to add a compartment for the generator is to Photoshop it into the photo!

OK, the new box arrived, so I just had to sit it on the rear bumper and take a photo to see what it looked like. Besides, I also had to make sure it would really fit between the relocated spare tire and the outside shower. Just barely.

FYI, the box weighs 31.8#.

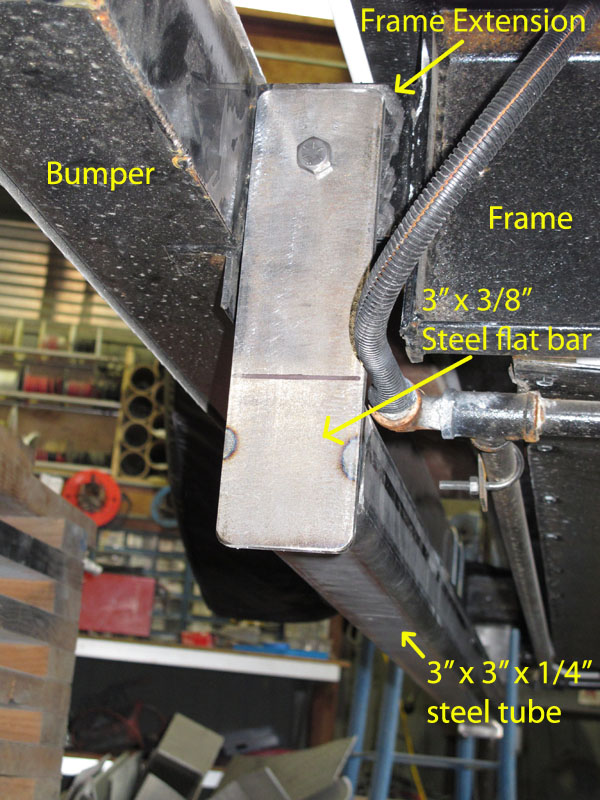

We started out by welding two 3/8" x 3" steel flat bars to a 3" x 3"x 1/4" steel tube as the foundation. The flat bars are bolted to the OE frame extensions that support the bumper. They'll also be welded once everything is fabricated and test fitted.

A view of the project underway in my neighbor's boat yard shop.

A view of the assembly being test fitted before final welding of the components.

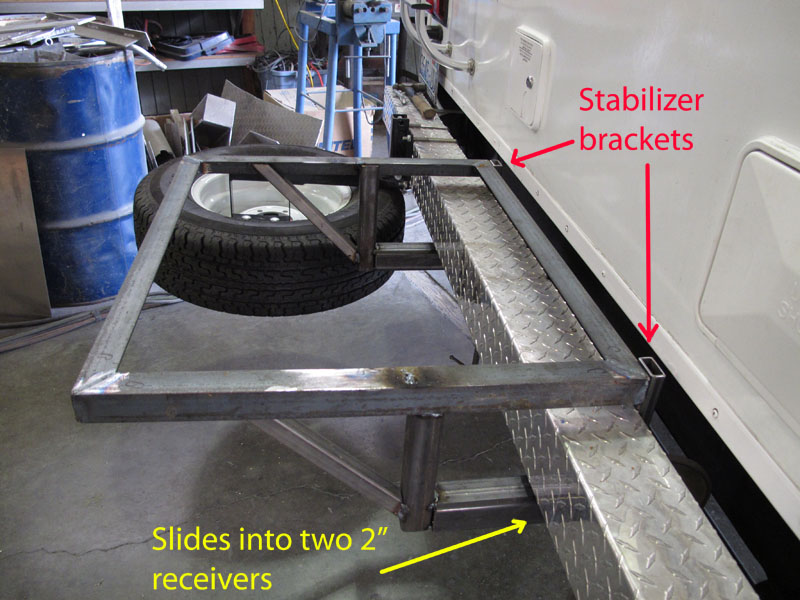

The frame for the generator box is removable from the foundation. The two 2" square tubes of the lower frame slip into two receivers on the foundation tube. The upper frame is bolted to the two uprights to stabilize it & prevent vibration from stressing the weight bearing components.

The founddation tube with the two 2" generator frame receivers tack welded in place.

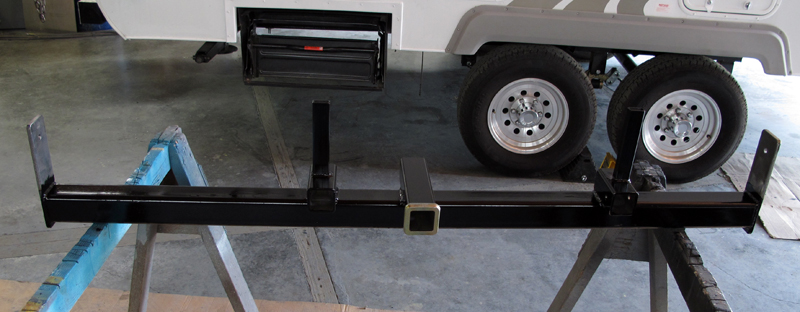

The foundation tube removed from the trailer for final welding. A third general purpose receiver will be welded to the center of the tube where it's been prepped for welding.

Welding completed and two coats of POR-15 and the foundation tube is ready for final installation.

FYI: the completed foundation tube assembly weighs 66.9#.

Another view of the foundation tube.

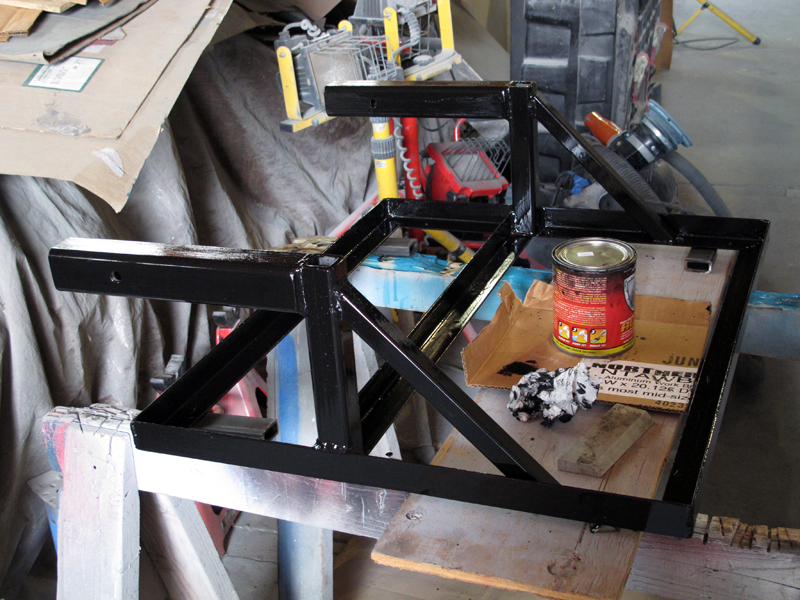

The generator support frame is also completed and coated with two coats of POR-15.

FYI: the frame section weighs 32.8#

The complete assembly sitting on saw horses before installation.

The foundation has been welded to the frame extensions and the generator frame installed.

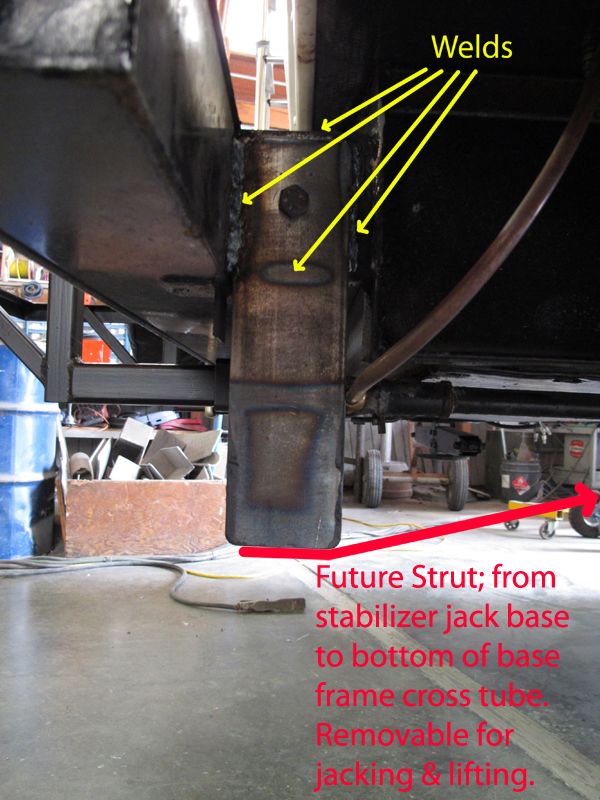

The welding of the foundation to the frame extension. Note how we did not make any alterations of any kind to the actual frame of the trailer.

I'll be adding a heavy-duty strut between the foundation tube and the base of the trailer stabilizer jacks. The strut will serve 3 purposes:

The completed generator compartment.

The completed generator compartment.

Note the sound board lining the compartment. The sound proofing & carpeting added an additional 10# to the compartment. The complete assembly: foundation tube & receivers, generator support frame, compartment, generator, 5 gallons of fuel plus the fresh water hoses, filter and supplies weighs 260#. Since the generator is 9 feet from the the axles and the pin is 18 feet from the axles, this results in a 130# reduction in pin weight. Our actual fully loaded pin weight, including a full tank of water, is 1550# which is 16.8% of the Fox's 9,250# gross weight. The pin weight will increase once we complete the new spare tire mount under the front of the trailer and add a second spare truck tire mount to the pin box. In other words, our net pin weight is OK now and will only get better as we complete our modifications and load the trailer for the outback.

The plan was to route the exhaust out of the compartment via the stainless steel marine cowl, however the cowl is not large enough to also move the engine cooling air, so the current solution is to turn the generator and have it exhaust both directly out of the open door. We'll probably upgrade to the Yamaha 2400 next year. The Yamaha exhausts out the right side so that will avoid the issue of heat on the spare tire as well as give us enough capacity to run the heat pump.

BTW, the cowl had the effect of creating a noticeable rap in the exhaust. Something we should be able to avoid by having a larger exhaust vent for both the engine cooling air and exhaust.

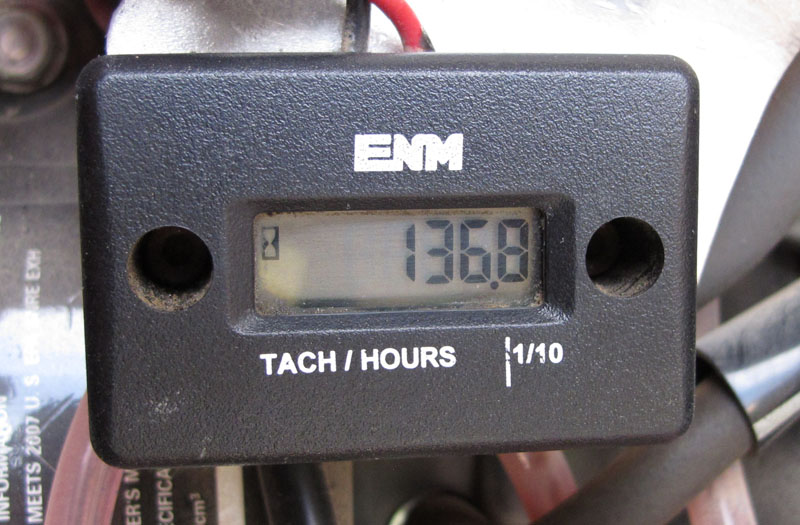

Some folks asked about the hour meter on our little Honda. Well, here it is. It indicates hours when the generator is off, and RPM when it is running. We got it on eBay for about $40.