of the

engine.

of the

engine.Use flare wrenches on the fuel line connections to avoid rounding the corners of the fittings. You won't need them very often, but if you mess up a fitting using your good ol' crescent wrench, don't say I didn't warn you. If you don't have a set of flare wrenches, get them now before you start. Sears has them for a fair price.

Take photos of the way it looks now.

Your engine might not look qui te like mine, and you might want to refer to

those photos later. If you don't take photos now, Uncle Murphy may drop

by just to annoy you.

te like mine, and you might want to refer to

those photos later. If you don't take photos now, Uncle Murphy may drop

by just to annoy you.

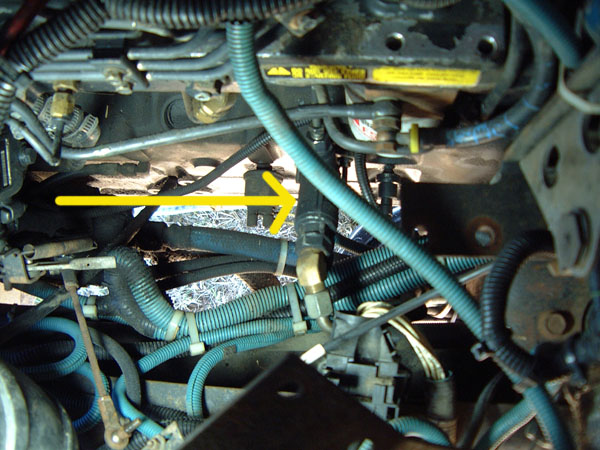

Move the throttle cable, transmission

cable and anything else out of the way that you need to for access to the

transfer pump.

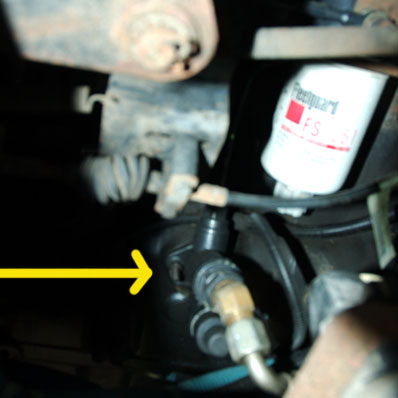

Loosen the fittings on the fuel lines.

I like to always break all the lines loose before I actually disconnect them.

That way, when I run into something that doesn't come apart I won't be getting

crud into the line that I had opened up.

Disconnect the fuel lines from the transfer pump. Wrap the open ends of the fuel lines. Those blue mechanic's paper towels and rubber bands work well.

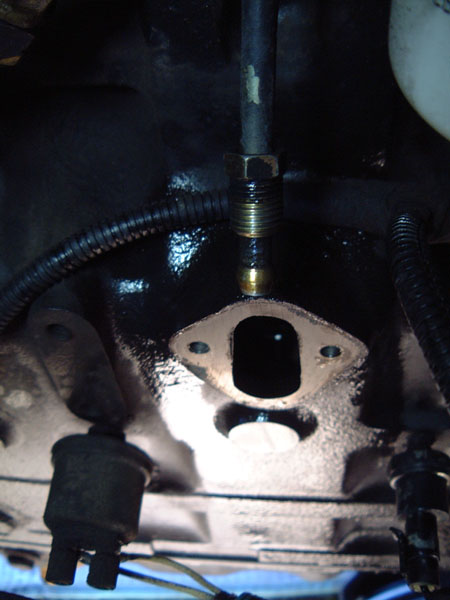

Loosen the two screws that hold the fuel

transfer pump to the engine block with your 10mm socket wrench. Remove

both screws and remove the pump.

Clean off the gasket surface on the engine block. A gasket scraper, putty knife or razor blade works well. Just don't scratch the mounting surface or get pieces of gasket into the open hole in the block.

Compare the old pump and the new pump

- Make sure you got the right pump

- Move any fittings

from the old pump to the new pump

Hold the new pump in the area and begin to connect the fuel lines. Leave them loose. It's just easier to get the threads started when the pump can be wiggled around a bit to line things up.

Position the new pump with gasket against the block and start the mounting bolts. OOPS! The pump won't fit up against the block

- The lobe on the camshaft is 'up' and pressing against the pump push rod preventing the pump form fitting up against the block. It will only get about 1/4" away and you can't press hard enough to make it fit.

- Two solutions:

- Get out your engine barring tool and rotate the engine until the camshaft lobe allows the pump to fit up nicely against the block, or

- "Bump" the engine with the ignition key. That means turning the key to the 'Start' position and immediately turning it back off. If you are quick, the engine will rotate a bit and sooner or later you'll find a spot on the cam where the pump will drop into place. If you aren't quick, the engine will start. So, if you are going to try this technique make sure nothing and nobody is around anything that might move if the engine starts. If it does start, it will immediately shut down because you remembered to turn the key off immediately. You did remember, didn't you?

- If the idea of the engine starting while you're bumping it with the starter, then disconnect the fuel shut-off solenoid.

Tighten the pump mounting screws to the proper torque; 18 ft-lb for my C8.3.

Now, tighten those fuel lines you left nice and loose in step 9.

Reconnect anything else you might have disconnected to get access to the fuel transfer pump.

Double check everything

- Are the fuel line fittings tight?

- Are the pump mounting bolts tight?

- Is the fuel-shut off solenoid connected?

- Are the throttle cable & transmission cable connected?

- Is there anything on or around the engine that shouldn't be?

Start the engine

- Oh-oh. The engine won't start.

- Did it start when you bumped it with the starter?

- If so, you may have sucked some air into the fuel injection pump.

- Bleed the fuel system and it should start OK.